rockwell hardness test b aluminium|rockwell hardness scale for aluminum : discount store Rockwell Hardness Testing Reference Guide. ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your . Resultado da CAM 2024. Ficção Americana. 7.2. EM ALTA 2023. O Sequestro do Voo 375. 8.3. EM ALTA 2023. Upgrade: As Cores do Amor. 7.1. EM ALTA 2024. A .

{plog:ftitle_list}

Rodízio com pizzas excelentes, bebida gelada, serviço rápido, atencioso e de primeira. Inclusive temos a opção de refil com refrigerante liberado. Consulte os valores com a .

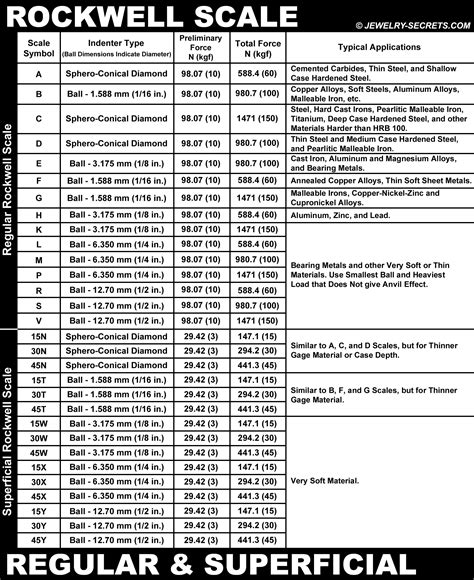

The hardness of aluminum can be assessed through various testing methods, including Brinell hardness and Rockwell hardness. The hardness of aluminum alloys is related to the other metals they are alloyed .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .

Rockwell Hardness Testing Reference Guide. ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .

The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented . The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell . The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a .

Hardness testing is commonly used for material evaluation due to its simplicity and low cost, relative to other assessments of these qualities. Rockwell hardness does have a relationship to tensile strength in some .

Rockwell Hardness Test. The Rockwell hardness test is based on the indentation depth caused by a diamond or a ball indenter under different loads. There are two main scales used in the Rockwell test: the Rockwell HRC scale .

The Rockwell B (HRB) scale is used for aluminum and structural steels (softer materials) while the Rockwell C (HRC) scale is used for high carbon alloy steels (harder metals). These tests use .materials such as steel-copper alloys, aluminum and plastics to name a few. Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell .

Hardness Conversion for Rockwell B Scale or Low Hardness Range . Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. .Rockwell hardness test sesuai ISO 6508 / ASTM E18. . Rockwell hardness (HR) kemudian dapat dihitung menurut rumus yang ditentukan dalam standar ISO 6508 dengan mengacu pada skala Rockwell yang diterapkan. . Aluminum .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .Aluminum 6061-T6; 6061-T651. Subcategory: 6000 Series Aluminum Alloy; Aluminum Alloy; Metal; Nonferrous Metal. Close Analogs: . Converted from Brinell Hardness Value: Hardness, Rockwell B: 60: 60 Converted from Brinell Hardness Value: Hardness, Vickers: 107: 107 Converted from Brinell Hardness Value: Ultimate Tensile Strength: 310 MPa:

rockwell hardness scale for aluminum

International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in reporting test results. Everyone in the steel industry recognizes the Rockwell hardness scale.

rockwell hardness chart for aluminum

40 40 Converted from Brinell Hardness Value Hardness, Rockwell B 60 60 Converted from Brinell Hardness Value Hardness, Vickers 107 107 Converted from Brinell Hardness Value Tensile Strength, . Aluminum, Al 95.8 - 98.6 % 95.8 - 98.6 % As remainder Chromium, Cr 0.040 - 0.35 % 0.040 - 0.35 %A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics.

Brinell hardness of 2024 aluminium alloy depends greatly on the temper of the material, but it is approximately 110 MPa. Brinell hardness of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is approximately 95 MPa. Rockwell hardness test is one of the most common indentation hardness tests, that has been .

The hardness is inversely proportional to the depth of penetration. There are many Rockwell hardness scales, depending on the type of indenter and load used. For example, the Rockwell C scale uses a cone-shaped, diamond-tipped indenter with a 150-kg load. The Rockwell B scale uses a 1/16-inch diameter ball indenter with a 100-kg load.Rockwell A Hardness, Rockwell B 87 87 Converted from Brinell Hardness Value Hardness, Vickers 175 175 Converted from Brinell Hardness Value Ultimate Tensile Strength 572 MPa 83.0 ksi AA; Typical Tensile Yield Strength 503 MPa 73.0 ksi AA; Typical Elongation at Break 11.0 % 11.0 % AA; Typical; 1/16 in. (1.6 mm) Thickness

Hardness of 6061 Alloy. Brinell hardness of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is approximately 105 MPa. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the .

between Brinell hardness and Rockwell B hardness of austen-itic stainless steel plate in the annealed condition. 1.6 Conversion Table 6 presents data on the relationship between Rockwell hardness and Rockwell superficial hardness of austenitic stainless steel sheet. 1.7 Conversion Table 7 presents data on the relationshipHRB Rockwell B MPa HRC Rockwell C MPa; Aluminium: Aluminium 2024 T351 | 3.1355 AlCu4Mg1: 120 [~65]-Aluminium: Aluminium 5083 H111 | 3.3547 | AlMg4.5Mn0.7: 75 . The Rockwell hardness test is based on the .The most common type of hardness test is the Rockwell test. The Rockwell test encompasses a set of tests for different hardness ranges. The Rockwell B (HRB) scale is used for aluminum and structural steels (softer materials) while the Rockwell C (HRC) scale is used for high carbon alloy steels (harder metals). These tests use different types of .

Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. Brinell .Usually soft materials like 1018 mild steel will use the Rockwell B scale, which makes use of a 1/16″ rounded steel penetrator with a 100 Kg major load. . Minimum Thicknesses for the Rockwell Hardness Test. . Example: aluminum foil; It’s especially suitable for measuring extremely hard and brittle materials like glass and ceramic, since .

ferrex feuchtigkeitsmessgerät bedienungsanleitung

Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y

feuchtigkeitsmessgerät app

Rockwell hardness does have a relationship to tensile strength in some structural alloys, such as steel and aluminum. The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test .Hardness, Rockwell B : 60: 60: Converted from Brinell Hardness Value: Hardness, Vickers: 107: 107: Converted from Brinell Hardness Value: Ultimate Tensile Strength: 310 MPa: 45000 psi: . Aluminum 6061-T6 is the one of the most common types of aluminum metals used in the industrial world today. With its high strength-to-weight ratio and .

The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal . Rockwell B (HRB) Softer metals, Aluminum alloys, Non-hardened steels: Suitable for softer materials, fast: Limited for very hard materials: Quality control, non-hardened metals: . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material .

The article helps you understand principle and applications of the Rockwell hardness test method. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; Our History; Why Choose Us; Testing Types. . Cast iron, aluminum, and magnesium alloys bearing metal. F. 60 kgf. 1/16″ WC Ball. Annealed copper alloys, thin, soft .The Rockwell hardness test is an essential tool in material science, offering a fast and trustworthy way to measure how hard materials are, with a special focus on metals. . The ASTM D2674 standard specifies a method for determining the efficacy of an etchant used to prepare the surface of aluminum alloys for subsequent adhesive bonding .The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial Rockwell hardness tester: 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y Polymer/Plastic Scales Figure 1: Schematic hardness and conductivity loop showing the relationship of hardness and conductivity to the heat-treated condition of an aluminum alloy. Figure 2: Hardness and conductivity relationships for several different heat treatable aluminum alloys. Hardness of a part is measured using a typical Rockwell “B” hardness tester.

rockwell c hardness scale chart

We loved the bonus symbols found in the online slot. We appreciated the Wild symbol and the scatter symbol in this game. The wild symbol is a substitute for any other symbol in . Ver mais

rockwell hardness test b aluminium|rockwell hardness scale for aluminum